Pengrowth

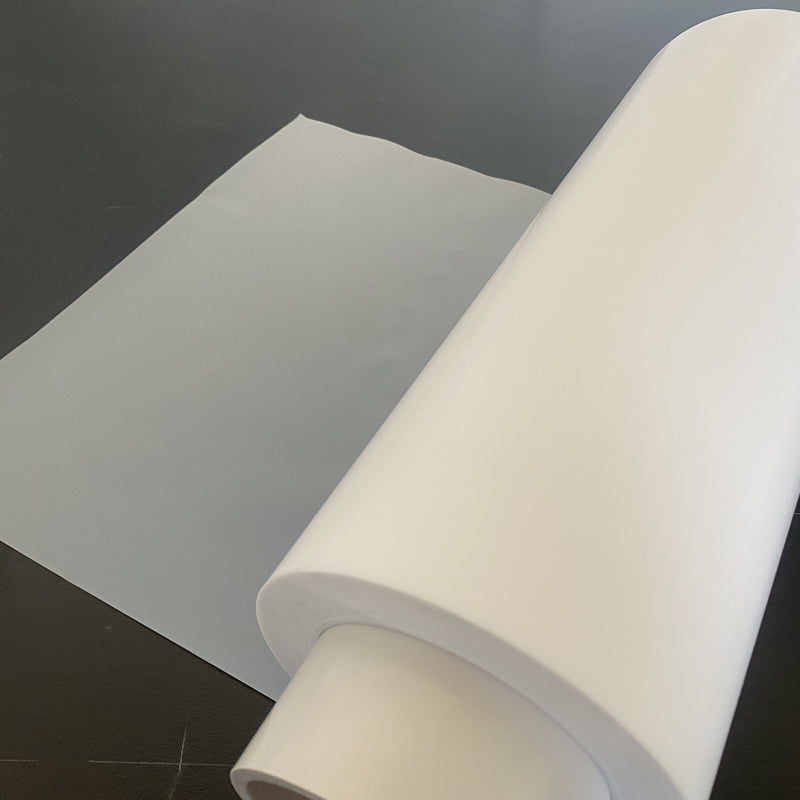

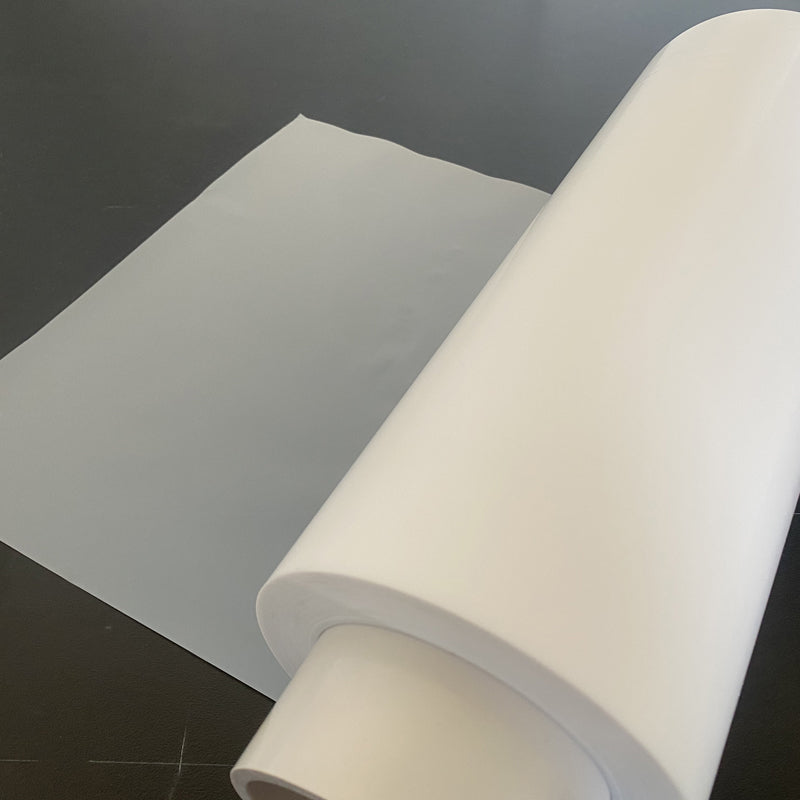

PTFE Hot Pressing Transfer Film for Hydrogen Fuel Cell Thin-Layer Electrodes

PTFE Hot Pressing Transfer Film for Hydrogen Fuel Cell Thin-Layer Electrodes

Couldn't load pickup availability

The film is made of polytetrafluoroethylene (PTFE) suspension resin and is processed into film products through molding, sintering, high-precision scraping and other processes. Professional manufacturing technology improves the product's surface smoothness and dimensional stability under high temperature conditions.

It has obtained RoHS and REACH certification, does not contain fillers and secondary materials, and meets safety and environmental protection standards.

Material: Polytetrafluoroethylene (PTFE)

Color: White (natural)

Size: Thickness: 0.1mm/ 0.13mm

Width: 150mm/ 320mm

Length: Customizable (any length)

Please contact us for length. Film is supplied in continuous lengths unless otherwise specified.

Performance characteristics

Share