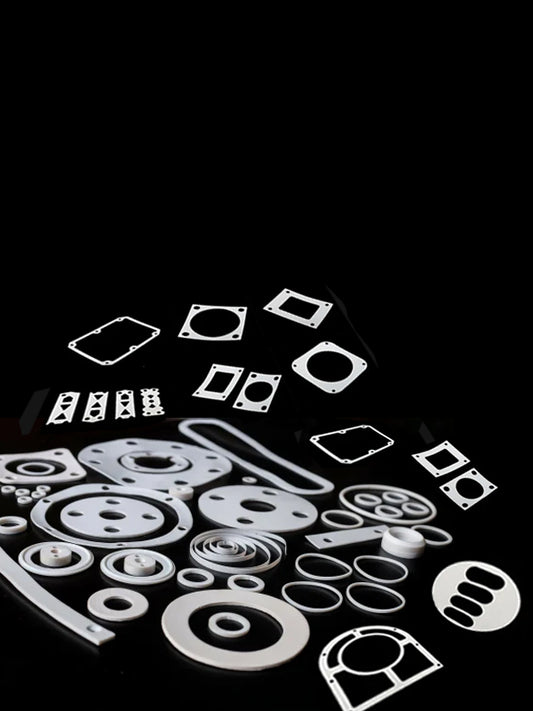

Collection: PTFE Compression Molding Process

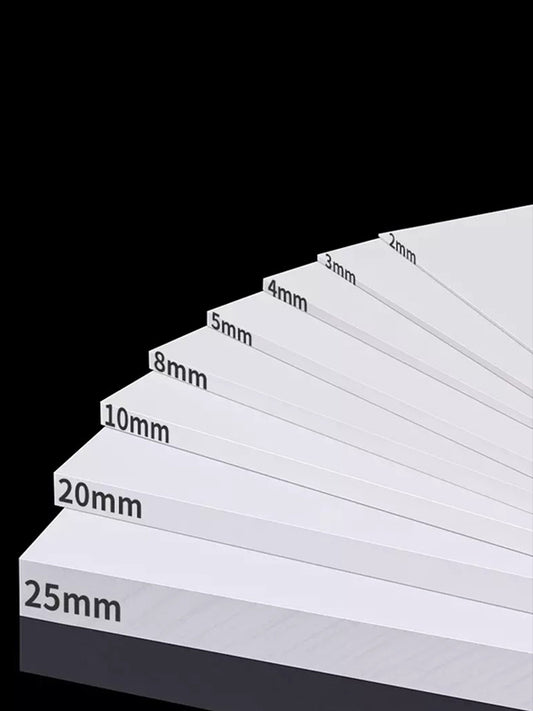

PTFE powder is loaded into molds, cold-pressed (20–50 MPa), and sintered at high temperatures (360–380°C) to form dense preforms, enabling production of complex-shaped components (e.g., flange gaskets, custom valve seats).

Advantages

- High-density homogeneity (2.15–2.20 g/cm³, porosity <0.5%)

- Batch production efficiency (3–5x faster than machining)

- Near-net shape forming (material utilization >98%)

- Customizable properties (e.g., glass fiber/graphite fillers reduce friction to 0.08)

Typical Products

- High-pressure flange gaskets (30 MPa resistance)

- Acid-resistant valve cores (withstands 98% sulfuric acid)

- High-frequency substrates (dielectric loss <0.0002)

- Artificial vascular membranes (thickness 0.05 mm ±0.005)