Pengrowth

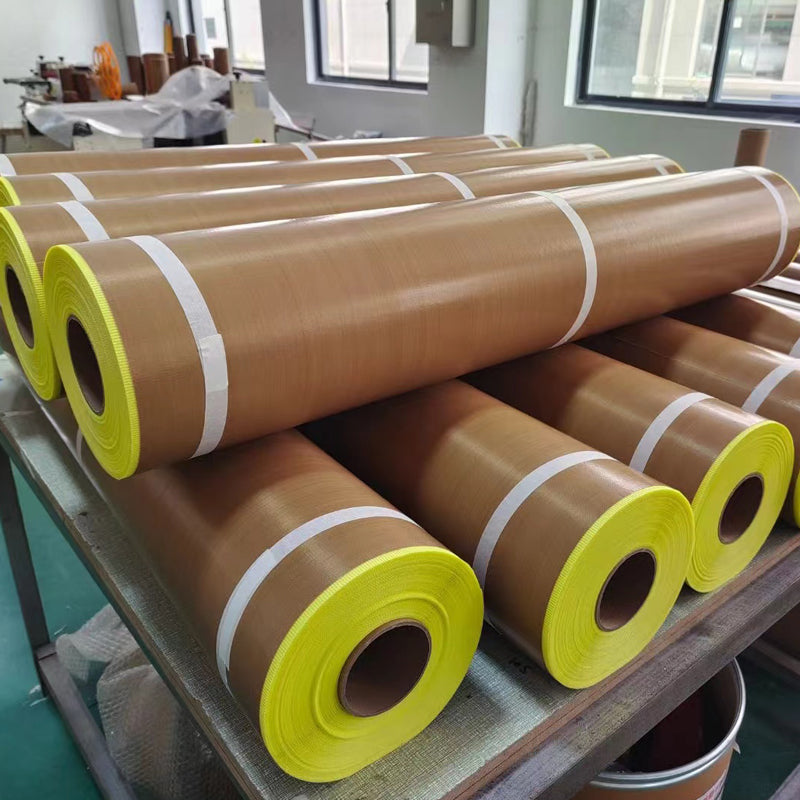

PTFE-coated Fiberglass

PTFE-coated Fiberglass

Couldn't load pickup availability

PTFE-coated fiber reinforced material is manufactured using premium alkali-free glass fiber as the base weaving material, woven via plain, twill, satin, or other patterns to form the reinforced substrate.The PTFE coating material, developed from internationally advanced raw materials and tailored to meet diverse industrial requirements, is processed into modified PTFE formulations. Finally, imported and upgraded coating equipment is employed to produce versatile utility materials in various thicknesses, widths, and applications.

Beyond exceptional weather resistance, abrasion resistance, low friction coefficient, and corrosion resistance, this material maintains its physical integrity without deformation across a temperature range of -170°C to +300°C. It is FDA-approved for extensive use in food processing, packaging, and related industries.

Material: Fiberglass, Polytetrafluoroethylene (PTFE)

PTFE Coated Kevlar Fabric

It is a high-strength, lightweight fiber renowned for its dimensional stability. This material performs reliably in humid environments and can withstand continuous exposure to high temperatures up to 200°C. It offers structural integrity and customizable mesh configurations, with the black variant providing enhanced anti-static properties.

Size:

Performance characteristics

- Weather Resistance: It can be used for a long time in a wide temperature range of -60℃~300℃. It can be placed at 300℃ for 200 consecutive days for aging test, and not only the strength will not be reduced, but also the weight will not be reduced. It will not age or crack at the ultra-low temperature of -180℃, and can maintain its original flexibility. It can also work at 360℃ for 120 hours without aging, cracking, and good flexibility.

- Non-Adhesiveness: Pastes, adhesive resins, organic coatings and almost all sticky substances can be easily removed from the surface.

- Mechanical Properties: Withstands compressive loads up to 200 kg/cm without deformation. Features ultra-low friction coefficient (0.05–0.1), excellent dimensional stability, and tensile elongation <5%.

- Electrical Insulation: Unique insulating properties with a dielectric constant of 2.6 and dielectric loss tangent below 0.0025.

- Corrosion Resistance: Resists nearly all chemicals, including strong acids and alkalis, without aging or deformation.

- Self-Lubrication: Ultra-low friction coefficient (0.05–0.1) enables oil-free operation. FDA and LFGB certified for food contact.

- Microwave & UV/IR Resistance: Stable under microwave, high-frequency, ultraviolet, and infrared exposure.

- Anti-Adhesion: Liners, gaskets, covers, conveyor belts for drying machinery, sealing tapes.

- Plastic Welding: Welding cloth, heat-sealing films, and pressure plates.

- Electrical Insulation: Insulation tape substrates, spacers, high-frequency circuit boards.

- Thermal Management: Laminated substrates, thermal insulation wraps,microwave-safe pads, oven sheets.

- Food Industry: Baking, freezing, defrosting belts; FDA-compliant processing and packaging.

- Industrial Coatings: Corrosion-resistant cladding for pipelines, flue gas desulfurization in power plants.

- Construction: Canopies for stadiums, stations, sunshades; architectural membranes.

- Specialized Uses: Flexible compensators, abrasive cutting discs, anti-static fabric(post-treatment).

Share