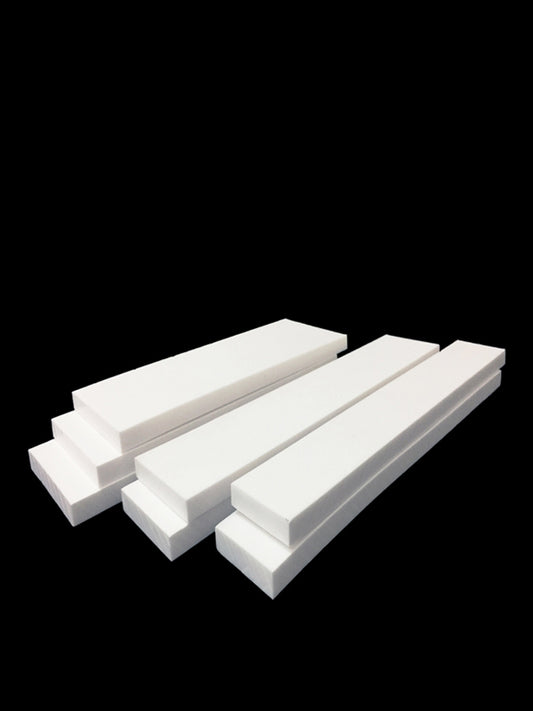

Collection: PTFE Turning Process

The process involves precision lathe machining of polytetrafluoroethylene (PTFE) through optimized tools, cutting parameters, and dry cooling. This achieves high precision (±0.02 mm) and low surface roughness (Ra 0.8-1.6 μm) while preventing material deformation and tool adhesion.

Advantages

- Extreme environment resistance

- Functional integration

- Cleanliness and safety

- Cost efficiency

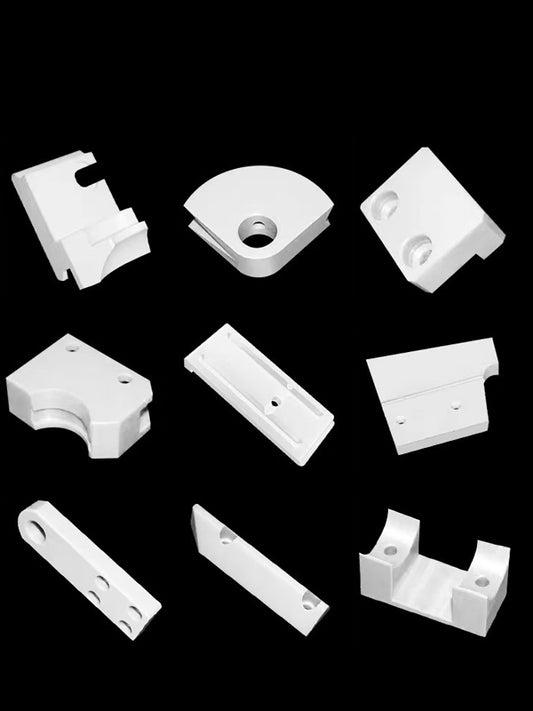

Typical Products

- O-rings, valve seats (pressure resistance 20 MPa)

- Bearing bushings (friction coefficient <0.1)

- Endoscope catheters (antibacterial surface treatment)

- Wafer carrier rings (electrostatic dissipative-grade PTFE)