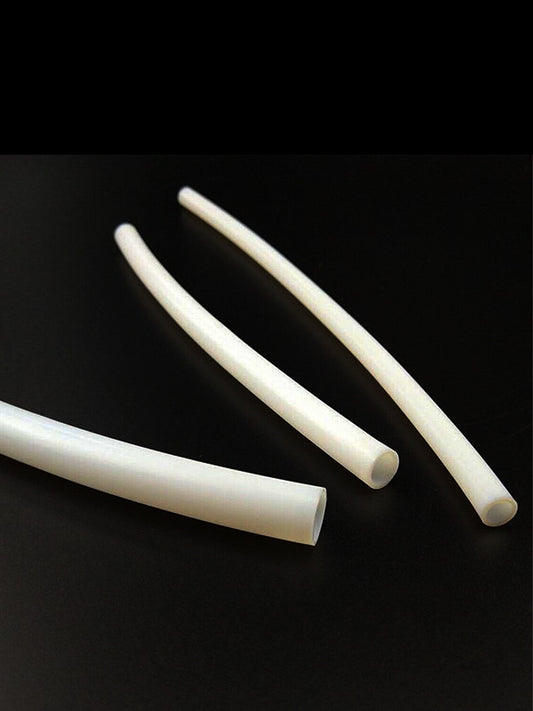

Collection: PTFE Extrusion Process

Pre-sintered PTFE resin is plasticized in an extruder (300-380°C) and driven through a precision die by a high-pressure screw (10-40 MPa) to continuously form tubes, rods, or profiles. Subsequent sintering ensures material densification.

Advantages

- High-efficiency continuous production

- Complex cross-section shaping

- Performance optimization

- Low material waste

Typical Applications

- Corrosion-resistant pipelines (DN10-DN300)

- 5G high-frequency cable insulation (dielectric constant 2.1)

- Expanded PTFE (ePTFE) sealing tapes (compression recovery >80%)

- Minimally invasive multi-lumen catheters (wall thickness 0.2 mm ±0.03)